- Capturing odors with water film

- Low pressure loss

- Minimizing sludge generation

- Running cost reduction

- Easy maintenance

Deoriser makes a difference compared to other scrubbers!

Four features of Deoriser

1 Capturing odors and dust

To say nothing of various odor-causing substances, fine powder dust can be captured reliably as well by the water film.

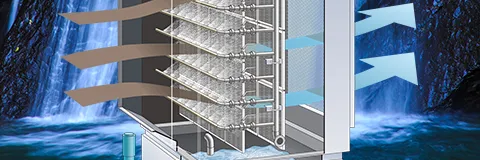

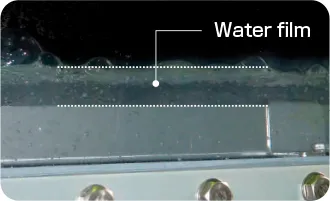

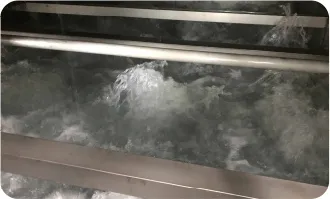

2 Capturing with water film

Water film formed on the screen realizes 100% gas-liquid contact efficiency.

3 Easy maintenance

Compared to conventional-type scrubbers, running costs are greatly reduced.

4 Minimizing sludge generation

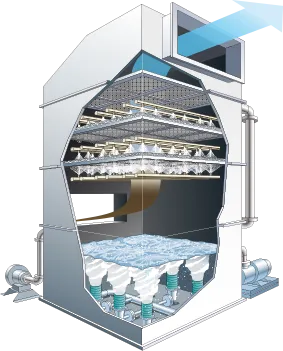

The air diffusion device Aquablaster is installed. Water putrefaction is prevented to minimize sludge generation.

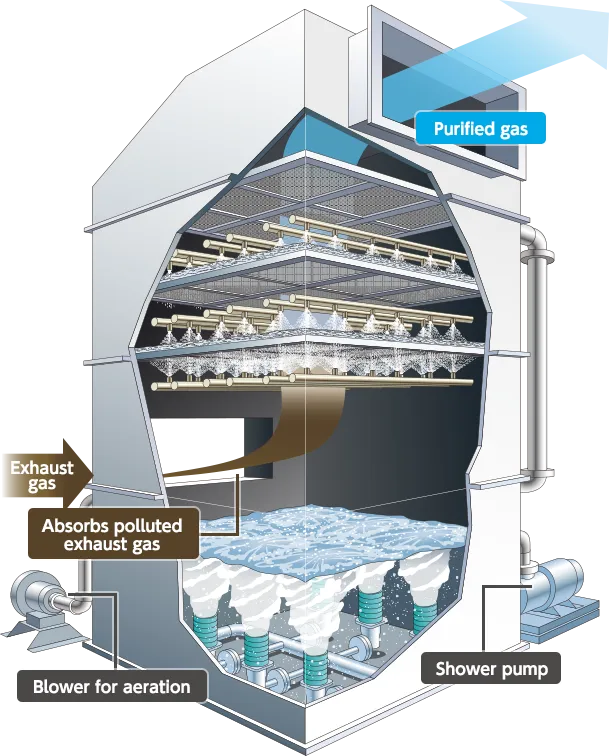

Water film type Scrubber Deoriser is an earth environment-friendly high performance scrubber equipped with a circulating water purification unit.

1 Capturing odor components and fine powder dust

Odors and dust are captured without fail.

2 Realizing 100% gas-liquid contact with water film

About 40 mm of water film shuts exhaust gas out.

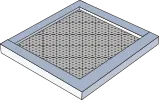

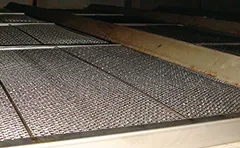

3 Adopting a cartridge-type screen

Replacement is easy with a screen 50 cm square.

4 Incorporating the Aquablaster

Water putrefaction is prevented to enable long-term use of circulating water.

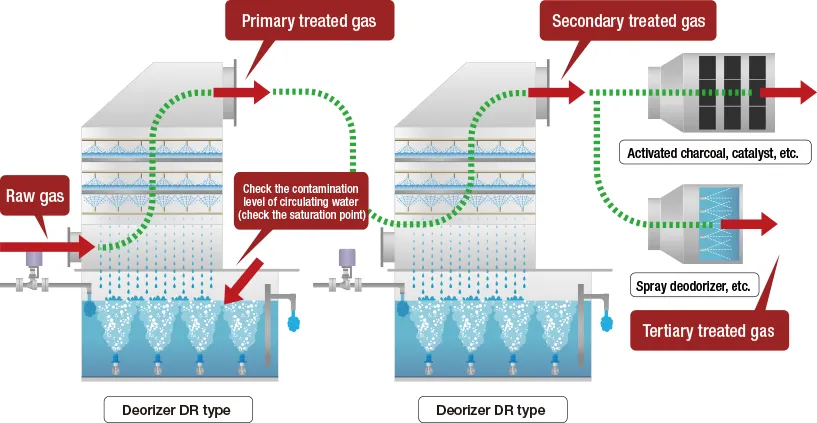

Next-generation deodorizing system that revolutionized the traditional concept of deodorization “Water film type Scrubber Deoriser”

Employing water film, high gas-liquid contact efficiency is realized to capture odor components without fail.

The interior of the tank is equipped with a diffusion pipe Aquablaster unit that biodegrades organic matter added to the water,

which minimizes circulating-water putrefaction and sludge generation, enabling long-term closed water circulation.

Water film type Scrubber Deoriser is a next-generation ultra-high-performance dust collection and deodorization unit that completely eliminated the weak points of conventional water cleaning scrubber type deodorizing equipment.

Unbelievable capturing power! Compare with other scrubbers!

Up to this volume was captured only in a few hours!

Here's the difference with other scrubbers!

- Capturing with water film ensures that odors and dust are captured without fail!

- Cartridge type contact material makes maintenance easy.

- Built-in high-performance diffusion pipe Aquablaster minimizes sludge generation and prevents water putrefaction!

Features of the Water film type Scrubber Deoriser cleansing deodorization unit

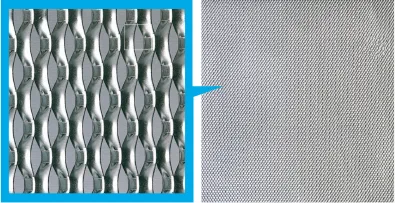

High gas-liquid contact efficiency is realized by forming water film on screens.

Special layered stainless-steel screen

Special layered stainless-steel screenEasy-to-replace cartridge type

Conventional scrubber A lot of infill material required

Conventional scrubber A lot of infill material required Deoriser Replaceable by only one person

Deoriser Replaceable by only one personHard to clog and makes pressure loss hard to change

Conventional scrubber Infill material clogged

Conventional scrubber Infill material clogged Deoriser Circulating water purification prevents clogging as well.

Deoriser Circulating water purification prevents clogging as well.The water film type Scrubber Deoriser prevents water from putrefying and makes sludge generation difficult.

Conventional scrubber Water putrefies, and sludge is generated.

Conventional scrubber Water putrefies, and sludge is generated. Deoriser Water is purified with the Aquablaster diffusion pipe.

Deoriser Water is purified with the Aquablaster diffusion pipe.The water film type Scrubber Deoriser responds to a wide variety of odor-causing substances in diverse plants.

Deodorization methods and business applications ○Application、△Conditionally applied、×Not application

| Method of deodorization | Printing plant | Paint plant | Casting and forging | Chemical plant | Food plant | Paper/pulp | Textile plant | Sewage/Garbage | Feed/Fertilizers | Restaurant | |

| Combustion | Direct combustion | △ | △ | △ | △ | △ | △ | △ | △ | △ | × |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Stored-heat combustion | ○ | ○ | △ | △ | △ | △ | △ | △ | △ | × | |

| Catalytic combustion | ○ | ○ | △ | △ | △ | △ | △ | △ | △ | × | |

| Adsorption | Fixed-bed collection | ○ | △ | △ | ○ | △ | △ | △ | △ | △ | × |

| Fluid collection | ○ | △ | △ | ○ | △ | △ | △ | △ | △ | × | |

| Honeycomb concentration | ○ | △ | △ | ○ | △ | △ | △ | △ | △ | × | |

| Replacement adsorption | ○ | △ | △ | ○ | △ | △ | △ | △ | △ | × | |

| Cleansing | Water | △ | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Acid / Alkali | △ | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | △ | |

| Oxidizing agent | △ | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | △ | |

| * | Deoriser | △~○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Biological deodorization | Soil filter deodorization | △ | △ | △ | △ | △ | △ | △ | ○ | △ | × |

| Scrubber deodorization | △ | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | × | |

| Packed tower deodorization | △ | △ | △ | △ | ○ | ○ | ○ | ○ | ○ | × | |

| Aeration deodorization | △ | △ | △ | △ | △ | △ | △ | ○ | △ | × | |

*Deoriser technology combines cleansing and biological deodorization.

Bio Deoriser odor reduction rates

| Substance | Concentration reduction rate for substance | Solubility in water | Neutralization | Flow-through velocity | |

| Nitrogenous compounds | Ammonia | ○ | 54g/100ml | Required | 0.75~1.0 m/sec |

|---|---|---|---|---|---|

| Trimethylamine | ○ | 108g/100ml | |||

| Dimethylamine | ○ | 23.7g/100ml | |||

| Diethylamine | ○ | Completely soluble | |||

| Sulfurous compounds | Methyl mercaptan | ○ | 2.3g/100ml | Required | 0.75~1.0 m/sec |

| Hydrogen sulfide | ○ | 0.67g/100ml | |||

| Methyl sulfide | ○ | Unknown | |||

| Methyl disulfide | ○ | Unknown | |||

| Aldehydes | formaldehyde | ○ | Completely soluble | Not Required | 0.5~0.75 m/sec |

| Acetaldehyde | ○ | Freely soluble | |||

| Propionaldehyde | △~○ | 22g/100ml | |||

| Normal butyraldehyde | △~○ | Unknown | |||

| Isobutyraldehyde | △~○ | 11g/100ml | |||

| Isomer valeraldehyde | △~○ | Unknown | |||

| Isovaleraldehyde | △~○ | Unknown | |||

| Isobutanol | △~○ | 8.7g/100ml | |||

| VOC | Ethyl acetate | △ | 8.7g/100ml | Not Required | 0.5m/sec以下 |

| Methyl isobutyl ketone | △ | 1.8wt% | |||

| Toluene | ×~△ | Insoluble | |||

| Xylene | ×~△ | Insoluble | |||

| Styrene | ×~△ | 30mg/100ml | |||

| Isopropyl alcohol | ○ | Completely soluble | |||

| Methylethylene | △~○ | 29g/100ml | |||

| Formaldehyde | ○ | Completely soluble | |||

| Propyl acetate | △ | 2.3wt% | |||

| Cyclohexane | ×~△ | Insoluble | |||

| Phenol | △~○ | 8.4g/100ml | |||

| PGME | ○ | Completely soluble | |||

| PGMEA | ○ | 20g/100ml | |||

| N-methyl-2-pyrrolidone | △~○ | Unknown | |||

| Acetone | △~○ | Freely soluble | |||

| Methanol | ○ | Freely soluble | |||

| Ethanol | ○ | Freely soluble | |||

| Fatty acid | Propionic acid | △~○ | Unknown | Required | 0.5~0.75 m/sec |

| Normal butyric acid | △~○ | Unknown | |||

| Normal valeric acid | △~○ | Unknown | |||

| Isovaleric acid | △~○ | Unknown | |||

*Figures indicate the average reduction rates for Deodorizer single shower specification, but these should be considered as references only as rates may vary depending on odor source concentration. We recommend performing an actual deodorization with a test device at the site in question.

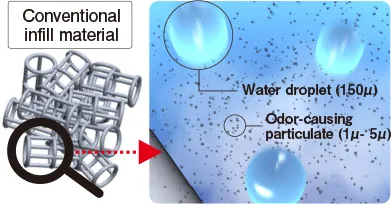

Why is water film necessary? Necessity of water film

Examining things at the microscopic level…

The width of net-type infill material is approximately 2 mm and the openings approximately 5 mm. Looking at the microscopic level, odor-causing particulates have a diameter of one to five microns, and the water droplets that dislodge these particulates are about 150 microns in diameter.

If we multiply these measurements by 1,000, we can visualize the particulates as 1 mm to 5 mm specks, and the water droplet the size of a softball, 15 centimeters across.

Now visualize the infill material as being the width of a narrow road – two meters – while the openings are five meters in width, and it is easy to see why the gas-liquid contact is poor.

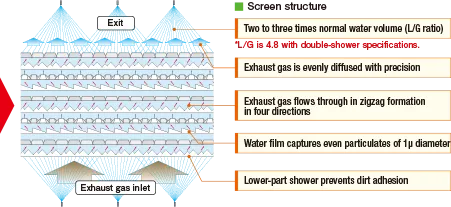

Gas-liquid contact mechanism

Ammonia (NH3) With gas volume 300m³/min, 50ppm⇒5ppm (90%reduction) Comparison chart| Remarks | Conventional scrubber | Deoriser | |

| Liquid(L) / Gas(G) | The higher the ratio of liquid to gas, the higher the gas-liquid contact efficiency. | 530L/min / 300m³/min L/G = 1.7 *When circulated water goes through one pass | 1960L/min / 300m³/min L/G = 3.2 *Water is circulated |

| Infill material thickness | A very important point is that infill material resists obstruction for easy maintenance. | 1,700mm *Causes obstruction | 40mm x 2 layers *Almost no obstruction |

| Pressure loss | Lower pressure loss means that fan consumes less electricity and energy efficiency is improved. | 700mmAq *Obstruction increases pressure loss | 800mmAq *No change in pressure loss |

Revolutionary, specialized multi-layered stainless steel screen comes as standard feature in all Deoriser units

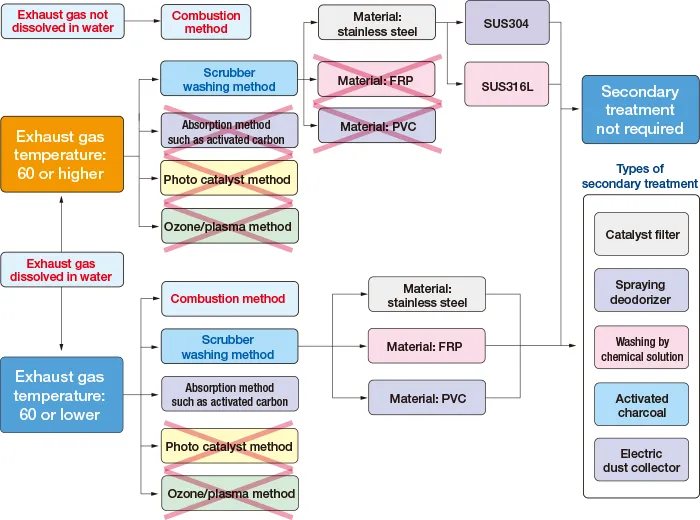

Treatment method determination flowchart

*An organic solvent may melt FRP and PVC.

*Including Deoriser, there is no perfect deodorization method. We recommend carefully checking and determining a treatment method by eliminating ineffective ones.

It is possible to carry out a demonstration experiment in the actual place.

By clarifying at which point the customer can be satisfied in a demonstration, various risks can be resolved.

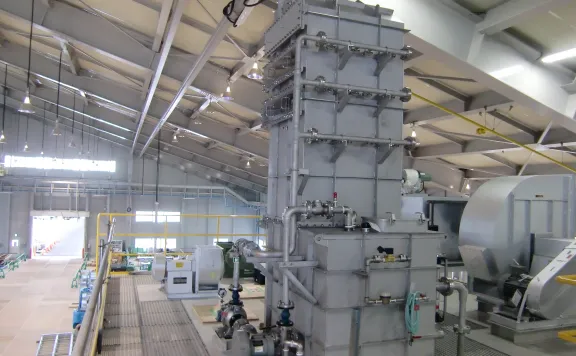

Applications/Supply record

Casting plant exhaust gas treatment

Casting plant exhaust gas treatment  Casting plant exhaust gas treatment

Casting plant exhaust gas treatment  Pharmaceutical plant exhaust gas treatment

Pharmaceutical plant exhaust gas treatment  Organic solvent exhaust gas treatment

Organic solvent exhaust gas treatment  Organic solvent exhaust gas treatment

Organic solvent exhaust gas treatment  Paint plant exhaust gas treatment

Paint plant exhaust gas treatment  Paint plant exhaust gas treatment

Paint plant exhaust gas treatment  Chemical plant exhaust gas treatment

Chemical plant exhaust gas treatment  Chemical plant exhaust gas treatment

Chemical plant exhaust gas treatment Deoriser circulating water treatment methods

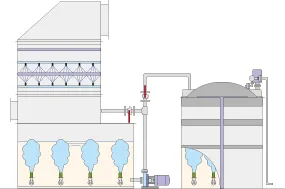

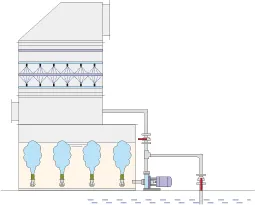

1 Settling tank purification method

This is a method in which water that has finished circulating is transferred to a separate tank and gradually treated. For example, five tons of circulated water treated over 90 days means that only 55 liters of water needs to be treated per day, minimizing the load on wastewater treatment facilities and enabling diluted discharge.

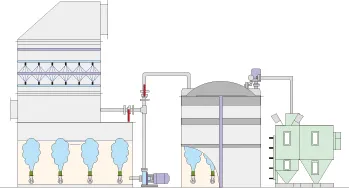

2.Water-treatment system simultaneous use method

This method entails installing an Aience unit tank side by side with the Deoriser and regularly purifying and discharging water. Depending on the rate of water circulation, oil separating system or coagulator may also be used. This method is geared toward businesses without wastewater treatment or sewage water facilities.

3.Sewage water discharge method

Circulating water is discharged at appropriate intervals at levels permissible under sewage water discharge standards. At first, it is necessary to perform a series of data measurements and determine the length of use that will result in levels exceeding the sewage water discharge standards. However, once these have been performed this is a highly labor saving method.

| Application | Duration between circulating water exchanges |

| Paint drying furnace exhaust gas treatment | 1 to 4 months |

| Chemical factory exhaust gas treatment | 1 to 4 months |

| Food factory exhaust gas treatment | 1 to 4 months |

| Restaurant exhaust gas treatment | 3 to 6 months |

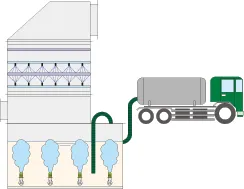

4.Industrial waste method

Circulating water is used continuously for as long as possible, and then disposed of as industrial waste. This method does not meet zero-emission targets, but it is suitable for businesses without wastewater or sewage water treatment facilities. The cost is reasonable as well, with five tons of circulating water being used for five months resulting in a per-ton cost of 35,000 yen, or 1,170 yen per day.

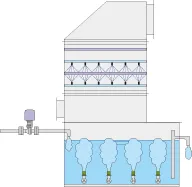

5.Fixed-quantity water injection method

Fixed quantities of water are injected, controlled by a solenoid valve, keeping the circulating water continually overflowing and water being discharged within the permissible water discharge standards. This method is largely geared toward businesses with access to groundwater or other reasonably priced water sources.

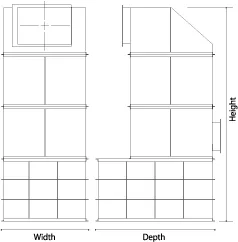

Water film type Scrubber Deoriser specifications table

| Model | DR-1W | DR-2W | DR-4W | DR-6W | DR-9W | DR-12W | DR-16W | DR-20W | DR-24W | DR-30W |

| Treatment air volume(m³/min) | 1~13 | 13~26 | 25~50 | 40~80 | 60~120 | 75~150 | 100~200 | 130~260 | 160~320 | 200~400 |

| Main unit pressure loss | 800 Pa in normal operation (1100 Pa when designed) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pump output/60Hz(kw) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 7.5 | 11.0 | 11.0 | 15.0 | 18.5 |

| Blower output/60Hz(kw) | 0.53 | 0.53 | 0.88 | 2.10 | 2.10 | 2.80 | 3.60 | 3.60 | 3.60 | 6.30 |

| Width (mm) | 1,050 | 1,400 | 1,400 | 1,400 | 2,000 | 2,000 | 2,480 | 3,000 | 2,686 | 3,050 |

| Depth (mm) | 2,300 | 2,300 | 2,300 | 2,470 | 2,640 | 3,145 | 3,145 | 3,300 | 4,060 | 4,100 |

| Height (mm) | 2,591 | 2,591 | 3,605 | 3,755 | 3,790 | 4,155 | 4,155 | 4,155 | 4,355 | 6,124 |

| Dry weight (kg) Pump, blower, and external piping excluded | 550 | 850 | 1,150 | 1,450 | 2,700 | 3,250 | 3,950 | 4,200 | 5,350 | 5,900 |

*Designs may be modified as needed.

*The shower washing section and the circulating water tank can be also separated.