- Reduced power consumption

- Reduced sludge output

- Zero odor generation

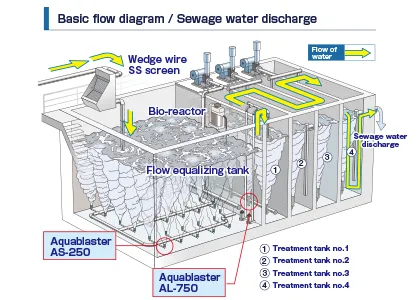

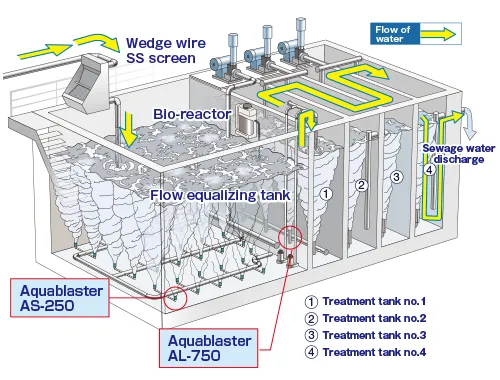

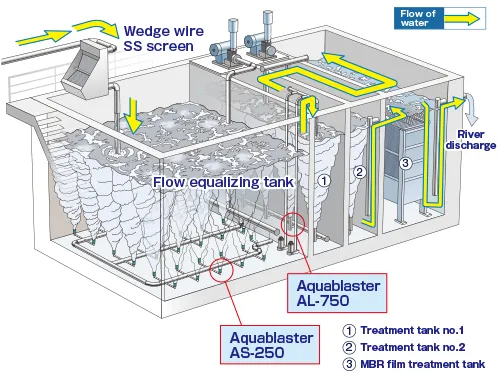

- Adjustment tank as a pre-processing tank

- Powerful stirring inside a tank

- Pressurized flotation unit elimination

- Sewage discharge without activated sludge

Aquablaster makes a difference compared to other diffusion pipes! Six features of Aquablaster

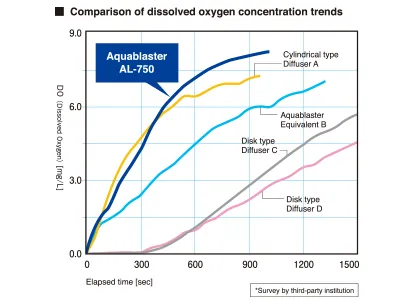

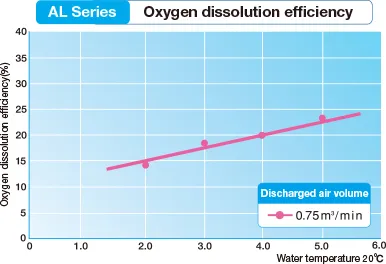

1 Outstanding oxygen dissolution power

Even compared to products of other manufacturers in this category, the top level of oxygen dissolution power is promised.

Levels of oxygen dissolution efficiency that have been open to the public cannot be used as indicators in comparison because of the lack of definite measurement criteria.

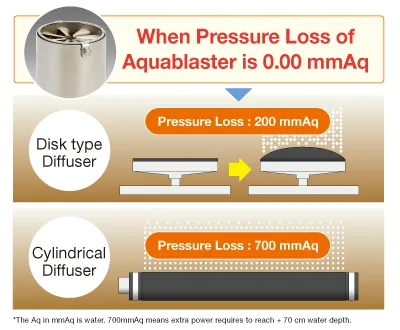

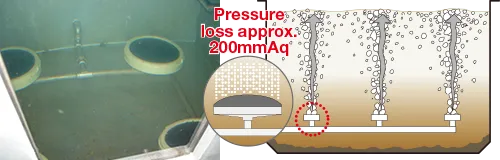

2 Reduced cost of electricity by Pressure Loss

Aquablaster with zero pressure loss has an energy-saving effect which consumes less electrical power than other diffusers.

3 Reduced sludge output

Sludge output is reduced because SS and oil content are pulverized into particles small enough for microorganisms to eat easily.

Pulverization of sludge is prevented by adjusting the air volume.

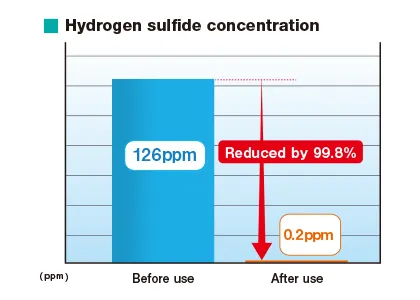

4 Guarantee of zero odor generation

Microorganisms are made to perform full aerobic respiration metabolism so that no odor such as hydrogen sulfide is generated.

Limited to the installations designed by Aience.

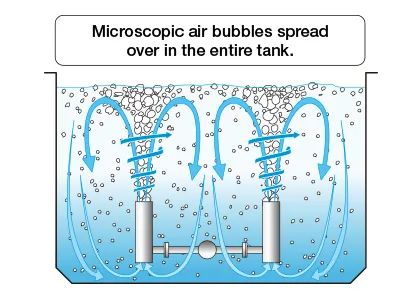

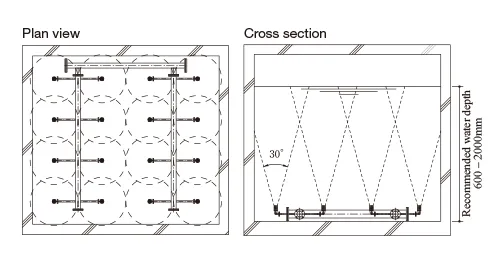

5 Powerful stirring inside a tank

Sludge on the bottom is swept up and its accumulation is prevented to eliminate anaerobic areas.

Such a substance as silica and calcium is also prevented from settling.

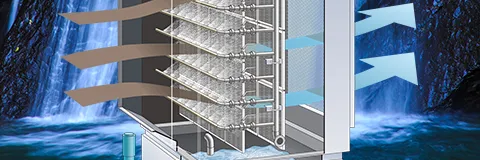

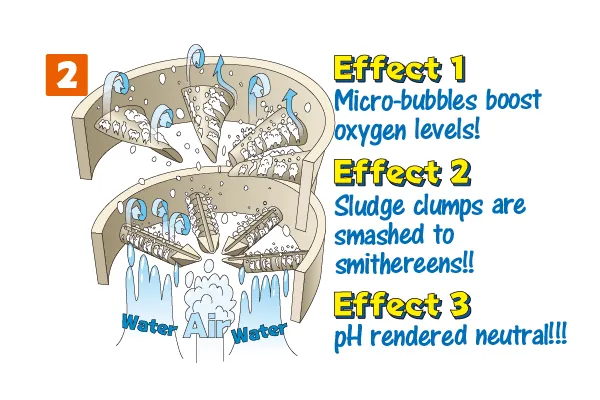

Energy-saving oxygen dissolution by using powerful currents! Both high oxygen dissolution efficiency and powerful stirring convection are realized.

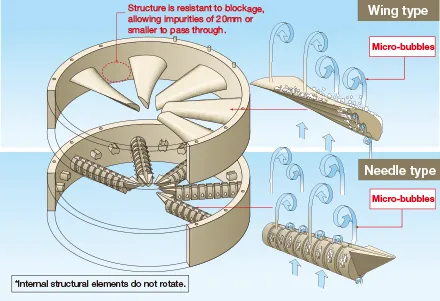

Microscopic air bubbles are generated by making the gas and the liquid collide with the blades in the Aquablaster diffuser pipe.

Excellent oxygen dissolution efficiency

Microscopic air bubbles are generated by making air collide with hard internal protrusions, which increase the dissolved oxygen concentration in high-load wastewater or circulating water. Oxygen is spread over the inside by the diffusion pipe to support microorganisms for aerobic respiration and maximize metabolic and biodegradation capabilities.

Major savings with Aquablaster

Treatment with Aquablaster alone enables discharge into sewage water.

Incorporate Aquablaster into your existing water tank, and there is no need for a pressurized flotation unit.

Electricity bills are dramatically lower when diffuser is replaced with Aquablaster.

Circulating water lifespan is extended by a factor of 5 to 20 and sludge volume drastically.

Although in the past our claims, of assimilating oils and SS, etc. with aeration and biological treatment only and no activated sludge or pressurized flotation unit, have been considered far-fetched according to the conventional wisdom surrounding water treatment, we have built up a track record of over 15 years and have made over 100 deliveries of entire systems to customers including major plant operators, major baked goods plants and automakers.

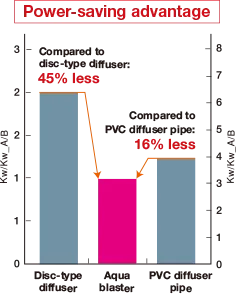

45% reduction in electricity consumption(compared to disc-type diffuser)

Experimental conditions

| MSLL: | 7600mg/L |

| Air volume: | 0.75m³/min |

| Water temperature: | 24-31℃ |

| No. of days : | 90 days |

While the initial cost may be somewhat higher, running costs are drastically reduced as there is no need to replace diffuser pipes and electricity bills are much lower.

Disc-type diffuser

Aquablaster

Stirring convection of micro-bubbles is the key to wastewater purification

- Sludge does not settle to the bottom easily.

- Microscopic air bubbles spread over the entire tank.

How well microorganisms can perform anaerobic respiration metabolism is an important point for the maintenance of the environment of a wastewater tank.

Pressure loss is even greater with tube-type diffuser

Reason why the processing capability of the Aquablaster

diffusion pipe is high

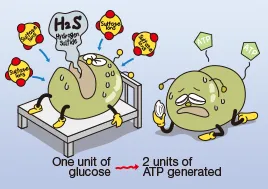

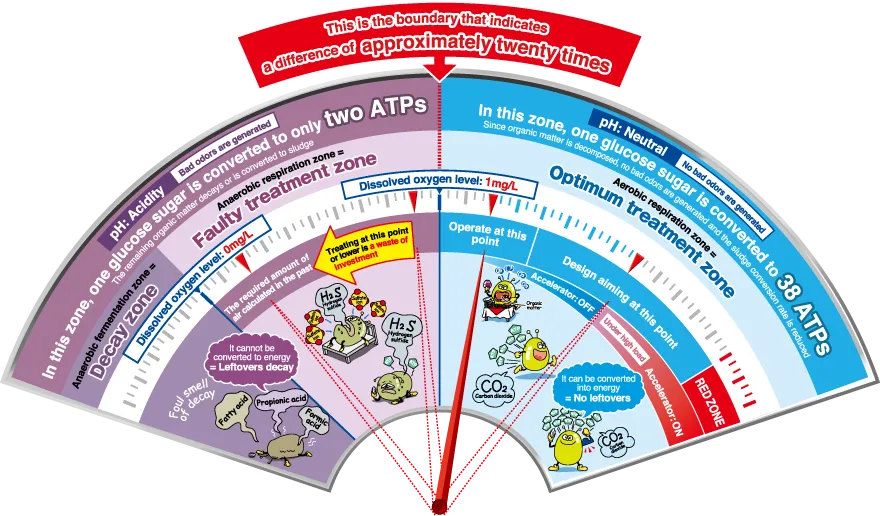

An unpleasant odor indicates that microorganisms' metabolism is weak.

*This is a very simple mechanism from a biology standpoint,

but for some reason, there is no other equipment on the market that applies it.

[Unpleasant odors and treatment mechanisms]

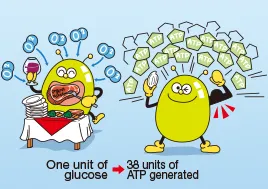

1. Aerobic respiration

When organic material enters the water, microorganisms begin to biodegrade itforcefully. In this process, however, they consume large amounts of oxygen.

Water treatment effective

2. Anaerobic respiration

When oxygen is rapidly consumed, the environment becomes bereft of oxygen and respiration of other substances such as sulfur ions begins. This is known as "anaerobic respiration," which generates byproducts such as hydrogen sulfide.

Water treatment ineffective

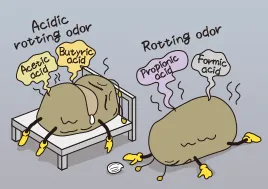

3. Anaerobic fermentation

When sulfur ions start to be consumed as well, the process turns to "anaerobic fermentation" and putrefactive gases such as acetic acid, butyric acid, and propionic acid gas are generated.

Water treatment ineffective

4. Aerobic respiration

Aquablaster facilitates the aerobic respiration of microorganisms for efficient water treatment without putrefaction.

Water treatment effective

Poor metabolic efficiency indicates that effective water treatment is not taking place.

*Aience 100% guarantees no foul odors are generated (at Aience design stage)

It is not the type of microorganism that is important, but their metabolism.

Metabolic efficiency varies by as much as 20x depending on the DO (dissolved oxygen) concentration in water. Once the oxygen level enters this zone, efficiency will plummet and your equipment investments will have been wasted.

Applications/Supply record

Industrial wastewater treatment

- Treatment of wastewater from food processing

- Treatment of wastewater containing mineral oils

- Treatment of wastewater from livestock farming

- Treatment of wastewater from industrial waste processing

Purification and recycling of circulating water

- Purification and recycling of circulating water for washing

- Sludge reduction and recycling of circulating water for solvent-based paints

- Purification and recycling of circulating water for water-based paints

Prevention of rotting in building cesspits

- Purification of building cesspit wastewater and prevention of rotting

- Prevention of rotting odors from grease traps

Other

- Ground water treatment

- Pond purification

- Product mixing

- Dust collection and deodorization of low air-volume gases

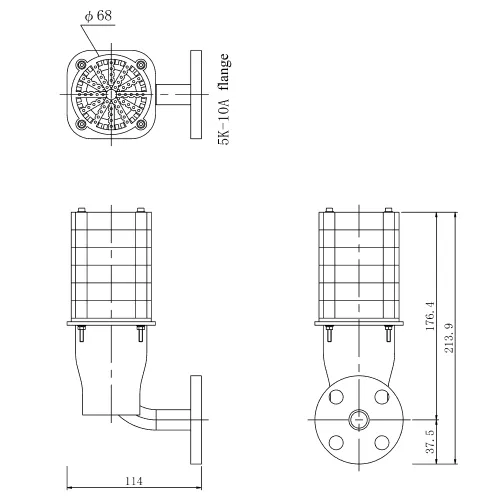

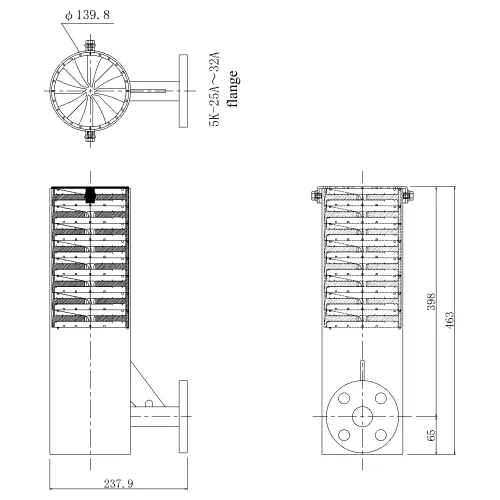

Aquablaster diffuser pipe standard specifications

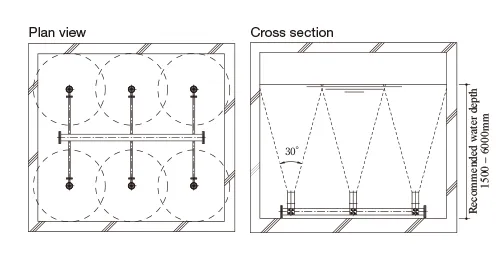

*Installation is generally performed so that wave bursts sweep across the water surface, but this does not necessarily apply depending on load, etc. Feel free to consult Aience.

(Unit: mm)

Specification table

| Product name | Part number | Applied air volume | Size | Connecting part |

| Aquablaster | AS-250 | 175~275L/min | W114×H213.9 | 5K-10Aflange |

| AL-750 | 600~900L/min | W237.9×H463 | 10K-25Aflange | |

| AL-1100 | 900~1300L/min | W237.9×H463 | 10K-25Aflange | |

| AL-1500 | 1300~1700L/min | W237.9×H463 | 10K-32Aflange |

*Air volume can be adjusted or unit produced to custom specifications.

Do not hesitate to consult Aience!